Description

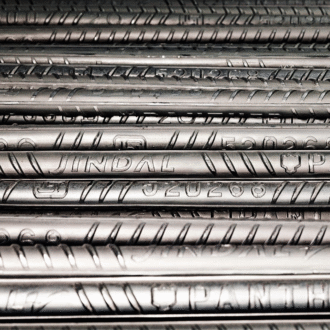

| Grade |

Fe 500D

|

| Single Piece Length |

12m

|

| Usage/Application |

Construction

|

| Material |

Mild Steel

|

| Brand |

Jindal Panther

|

| Country of Origin |

Made in India

|

| Thickness |

25mm

|

| Carbon, Max |

0.25

|

| Sulfur, Max |

0.04

|

| Phosphorus, Max |

0.04

|

| S+P, Max |

0.075

|

| Carbon Equivalent(CE) |

0.42

|

| Yield Stress (N/mm2) Min |

500

|

| Elongation(Min) |

16

|

| Tensile Strength(N/mm2) Min |

565

|

| UTS/YS Ratio |

1.13

|

Product Description:

TMT Rebars are integral to every construction project. During construction TMT rebars and concrete complement each other in a way that Reinforced Cement Concrete (RCC) structure can be moulded into any desired shape, with the rebars providing the requisite tensile strength to withstand the load.

Jindal PantherTM TMT Rebars are technologically advanced thermo-mechanically treated rebars which are superior to ordinary TMT in the market, owing to the state-of-the art manufacturing technology from leaders in rebar production- namely, HYQST Technology from MORGAN of USA (now Siemens USA), HYQST technology produces Rebars with high strength, high ductility and bendability and high weldability surpassing the requirements of Fe500D, 550D and 600CRS rebars.

Jindal PantherTM TMT Rebars are available in the following sizes as per IS: 1786-2008 for Concrete Reinforcement (in mm): 6 8 10 12 16 20 25 28 32 36 40 45* 50*

Features:

Excellent Bonding With Cement:

Uniform And Parallel Rib Pattern-Jindal PantherTM TMT Rebars have precise, uniform and parallel rib pattern engraved through computer controlled notch making machines, which results in excellent bond strength with concrete.

Superior Weldability:

Low Levels Of Carbon-Low levels of carbon ensure easier and faster welding without preheating. This means stronger and safer weld joints & reduction in wastage during welding at site.

Earthquake Resistant Properties:

High UTS/YS-Jindal PantherTM TMT Rebars are proven to have higher resistance to cyclic loading conditions and are recommended in earthquake prone areas due to their superior seismic resistant properties.

Jindal PantherTM TMT Rebars meet international specifications for the UTS/YS ratio thus imparting them with strength and high ductility.

Excellent Bendability:

HYQST Technology-Due to the highly controlled process that ensures a microstructure with a soft (ferrite and pearlite) core, Jindal PantherTM TMT Rebars have excellent bendability (in spite of their high strength). This facilitates easy bending, making work easier and faster at construction sites.

Corrosion Resistant:

The parallel rib pattern in Jindal PantherTM TMT Rebars created in the final finishing eliminates the chance of torsion residual stress. This coupled with low carbon content leads to superior corrosion resistant properties as compared to ordinary rebars.

Greater Resistance To Fire:

The quenching and self-tempering treatment at a temperature of approximately 650°c results in a consistent and thick layer of tempered martensitic-rim on the outer surface of the Jindal PantherTM TMT Rebars. This imparts higher capacity to retain strength at elevated temperatures.

Reviews

There are no reviews yet.